Element Materials Technology

Interested in working with

Element Materials Technology?

Overview

Materials Testing

As one of the largest independent testers of materials in the world, Elements team of Engaged Experts work tirelessly to test a diverse range of materials including metals, polymers, elastomers, composites and ceramics to make certain that they are safe, quality, compliant and fit for purpose in their end application.Product Qualification Testing

Element provides critical compliance, reliability and qualification testing to clients in the Aerospace, Transportation, Oil & Gas and Telecommunications sectors. Our services include Environmental Testing & EMC Testing for a variety of industries and highly specialized simulation testing programs for fuel systems, hydraulic and pneumatic component and systems and spin testing for the Aerospace sector.Speak with an Expert

Our team of Engaged Experts stand ready to assist you in solving your most demanding technical challenges. Contact us today to learn more about Element, or to request a quote for your next project.Standards & Methodologies

Element performs testing in accordance with a number of certification bodies and government agencies. Some of our more popular standards include:

American Society for Metals (ASM International)

ASTM International

British Standards (BS)

Euronorm (EU)

International Electrotechnical Commission (IEC)

International Standards Organization (ISO)

Society of Automotive Engineers (SAE)

Qualifications, Certifications, Accreditations & Licenses

Element's laboratories are accredited to ISO 17025 in the United States and United Kingdom, and RvA VCA in the Netherlands. In addition, our Aerospace laboratories hold the prestigious Nadcap certification in their particular fields of expertise. More information, including each of our laboratories' scopes of accreditation, can be found on our website.

Many of our labs also carry client and agency certifications for specific test types. Some of these certifications include:

Aerojet Rocketdyne

American Association of State Highway and Transportation Officials (AASHTO)

Airbus

American National Standards Institute (ANSI)

Boeing

General Electric

Honeywell

International Safe Transit Association (ISTA)

Lockheed Martin

National Aeronautics and Space Administration (NASA)

National Environmental Laboratory Accreditation Program (NELAP)

Northrop Grumman

Pratt & Whitney

Space Exploration Technologies (SpaceX)

Verizon

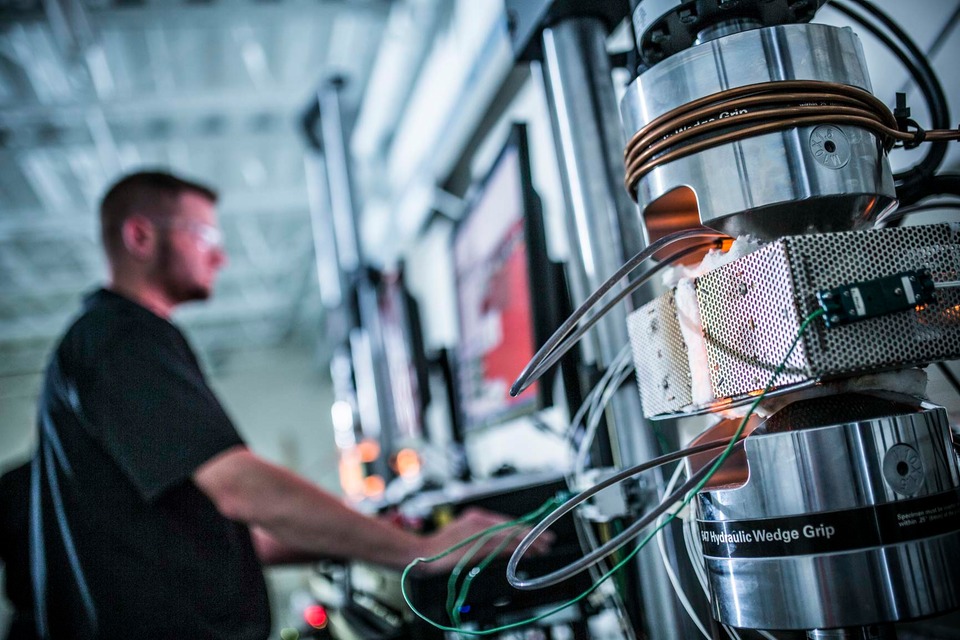

Lab Gallery

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)

Industries Served

- Acoustics and Sound Barriers

- Adhesives, Glues, and Tapes

- Advanced Materials

- Advanced Technology

- Aerospace, Aviation, and Aeronautical

- Aggregate

- Aromatics

- Automotive and Vehicles

- Batteries

- Beds and Bedding

- Bricks, Pavers, and Masonry

- Ceramics

- Circuit Boards

- Coatings and Finishings

- Composites

- Concrete and Cement

- Construction and Building

- Consumer Products

- Containers and Closures

- Dentistry and Dental Products

- Doors, Door Handles and Doorframes

- Electric Circuits

- Electronics

- Engine and Motors

- Fabrication and Assembly

- Fasteners and Connectors

- Fiber Optics

- Floors and Flooring

- Foundries and Forgery

- Furniture

- Gaskets and Seals

- Hardware and Tools

- Healthcare and Medical

- Highways, Roads, and Roadways

- Hydraulics

- Hydrocarbons

- Industrial Equipment

- Industrial Materials

- Industrial Water

- Machines and Machinery

- Manufacturing

- Medical Devices

- Medical Implants

- Medical Technology

- Metals

- Military and Defense

- Mining

- Natural Gas

- Oil and Petroleum

- Orthopaedics

- Orthotics and Prosthesis

- Packages and Packaging

- Paints, Colorants, and Dyes

- PCB's

- Pharmaceutical

- Photovoltaics

- Plastics and Polymers

- Polymer

- Power and Energy

- Printed Circuit Boards (PCB)

- Renewable Energy

- Rocks and Stones

- Rubber

- Soil

- Springs and Wire Forms

- Transportation

- Tubing and Tubes

- Volatile Organic Compounds (VOC)

- Walls and Partitions

- Waste Management

- Wireless Techology

Testing Types

- Abrasion

- Accelerated Weathering

- Acoustics

- Adhesion Strength

- Advanced Materials

- Ageing

- Air Pressure (Leakage)

- Analytical Chemistry

- Biomedical Engineering

- Carburization

- Case Depth

- Certification

- Chemical Residues

- Chromatography

- Cleanliness

- Colormetric

- Comparative Pharmacology

- Comparison

- Compatiability

- Composition

- Compression

- Contaminant

- Corrosion

- Creep

- crystallization

- Cure Behavior

- cure cycle determination

- Cytotoxicity

- Defect Analysis

- Deformulation and Reverse Engineering

- Degradation

- Design Review and Evaluation

- Design Verification Testing (DVT)

- Dezincification

- Dielectric Constant

- Dimensional

- Drop

- Durability

- Dynamic

- Dynamic Mechanical Analysis (DMA)

- Elasticity

- Electrical

- Electrochemical Corrosion

- Electromagnetic Compatibility (EMC)

- Electron Microscopy

- Electron Microscopy with Energy-dispersive X-ray spectroscopy (SEM-EDX)

- Electrostatic Discharge (ESD)

- Elemental Analysis

- Elongation

- Emissions

- Endurance

- Engineering and Process Design

- Environmental Assessments

- Environmental Stress Cracking (ESC)

- Environmental Toxicology and Ecotoxicology

- Etching

- ex vivo human tissue assays

- Extractables / Leachables

- Failure Investigation | Failure Analysis

- Fatigue

- Fire Resistance

- Flash Point

- Flexural Strength

- Fluid Dynamics

- Fluoresence

- Fretting Corrosion

- Friction

- FTIR Fourier Transform Infrared Spectroscopy

- GC/MS

- Genotyping

- Glass Transition Temperature (Tg)

- Hardness

- Hot Seal Strength

- HPLC

- Humidity

- Identification

- Impact

- In-Vitro

- In-vivo

- Inclusion

- inductively coupled plasma - optical emission spectroscopy (ICP-OES)

- Inductively Coupled Plasma Spectroscopy with Mass Spectrometry (ICP-MS)

- Ingress

- Ingress Protection (IP)

- Inorganic Chemistry

- Ion Chromatography

- Load

- Macrostructure Analysis

- Materials Characterization

- Mechanical durability

- Mechanical Properties

- Mechanical Shock

- Melt Flow Index (MFI)

- Melting Point

- Metallography

- Microanalysis

- Microstructure Analysis

- Moisture Resistance

- Non-Destructive (NDT)

- Optical Microscopy

- Particle Analysis

- Permeation/Permeability

- pH

- Pharmacology

- Plating Evaluations

- Powder X-ray Diffraction (XRPD)

- Pressure Cycling

- Product Design

- Product Safety

- Rapid Gas Decompression (RGD)

- Reformulation

- Rheology

- RoHS

- Safety

- Seismic

- SEM / Scanning Electron Microscopy

- Sensitization

- Shear

- Shear Stress

- Shock

- Simulation

- Softening Temperature

- Sour Gas

- Specific Gravity

- Spectrometry

- Spectroscopy

- Strength

- Stress

- Stress Corrosion Cracking (SCC)

- Surface Analysis

- Tear strength

- Tensile

- Tension

- Textile

- TGA

- Thermal and Thermodynamics

- thernal conductivity

- Tribology

- Unknowns Identification

- UV/Vis

- Vibration

- Viscosity

- Water Ingress

- Water Vapor Transmission

- Wear

- wear resistance

- Weathering

- Weld Qualitifcation

- X-Ray Fluorescence XRF

- XRD

Publications

Element Materials Technology has not posted any publications.

DISCLAIMER: This Laboratory Profile was provided by the company above.