The era of textiles serving purely aesthetic or basic functional roles is long past; today, advanced technical fabrics are the backbone of industries ranging from elite athletics to national defense, driven by specific, measurable, and highly demanding end-use requirements. This revolution necessitates specialized and meticulous performance textile testing, an imperative step that validates a material’s capacity to actively manage moisture, resist extreme forces, protect the user, and maintain structural integrity under persistent stress. The difference between a high-performing garment and a catastrophic failure often lies in the precision of laboratory verification. For manufacturers and product developers in the sportswear, medical, automotive, and military textiles sectors, comprehensive performance textile testing is the only way to transform ambitious functional claims—like enhanced moisture wicking or superior durability—into guaranteed, verifiable material properties that ensure both market competitiveness and user safety. This article details the essential testing pillars that define and validate the next generation of intelligent and specialized fabrics.

Defining the Benchmark: Essential Material Properties for Technical Fabrics

The foundational step in validating any specialized fabric involves confirming its core material properties. Unlike conventional textiles, the specifications for technical fabrics are often dictated by precise engineering metrics rather than hand-feel or appearance. These metrics are established through rigorous performance textile testing and must align perfectly with the intended application, whether it’s the high tensile strength required for geotextiles or the low thermal conductivity needed for protective insulation. This initial stage of testing establishes the baseline for quality control and provides the necessary documentation for compliance with industry safety standards.

Key Material Properties and Initial Testing:

| Material Property | Test Objective | Relevance to Technical Fabrics |

|---|---|---|

| Material Composition & Content | Verifying the exact fiber blend (e.g., carbon fiber, aramid) using chemical or microscopic analysis. | Ensures compliance with labeling requirements and confirms the presence of specialized fibers. |

| Mass per Unit Area (Weight) | Precisely measuring the fabric density (g/m² or oz/yd²). | Critical for military specifications, lightweight sportswear, and aerospace applications where weight impacts fuel consumption or speed. |

| Dimensional Stability | Assessing how much the fabric shrinks or stretches after washing, heat setting, or dry cleaning. | Crucial for maintaining fit and integrity in protective gear and tight-fitting sportswear. |

| Thickness and Compressibility | Measuring the precise distance between the fabric surfaces under a specific pressure. | Essential for insulation effectiveness, medical bandages, and filtration media. |

Furthermore, the electrical and thermal material properties of technical fabrics are increasingly important. For instance, conductive textiles used in smart wearables or heating elements must undergo precise resistance testing, while flame-retardant materials require specialized ignition and char-length analysis to ensure they meet stringent safety standards. Confirming these underlying material properties is the mandatory prerequisite for all subsequent functional testing.

The Science of Comfort: Assessing Moisture Wicking and Thermal Regulation

In high-performance applications like sportswear and tactical gear, the fabric’s ability to manage the user’s microclimate is as important as its physical strength. Moisture wicking refers to the capillary action that draws liquid sweat away from the skin, spreading it across the fabric surface for rapid evaporation. This process is vital for thermal regulation, preventing chilling in cold environments, and enhancing comfort during strenuous activity. Poor moisture wicking leads to saturated fabric, which increases weight, promotes bacterial growth, and dramatically impairs the body’s ability to cool itself.

Specialized performance textile testing methods are deployed to quantitatively measure the speed and efficiency of moisture management. These tests often track the vertical or horizontal wicking speed of water or synthetic sweat.

Key Tests for Physiological Comfort:

- Wicking Speed Test (e.g., AATCC 197): Measures the rate at which water travels along the fabric’s surface or through its structure. A high wicking rate confirms the moisture wicking claim.

- Moisture Management Test (MMT): Provides a dynamic analysis by tracking how quickly moisture is absorbed, transported, and diffused on both sides of the fabric. This gives a numerical index for the overall moisture wicking performance.

- Water Vapor Transmission Rate (MVTR): Measures how much water vapor (in the form of breathable perspiration) can pass through a fabric over time. High MVTR is critical for highly breathable outer layers and waterproof-breathable systems.

- Thermal Resistance (R-value): Essential for insulating layers and cold-weather gear, this test quantifies the fabric’s ability to resist heat flow, directly validating the material’s thermal material properties.

These comprehensive assessments allow manufacturers of sportswear and military textiles to substantiate their claims with hard data, ensuring their products genuinely deliver the thermal and comfort management benefits promised to the end-user.

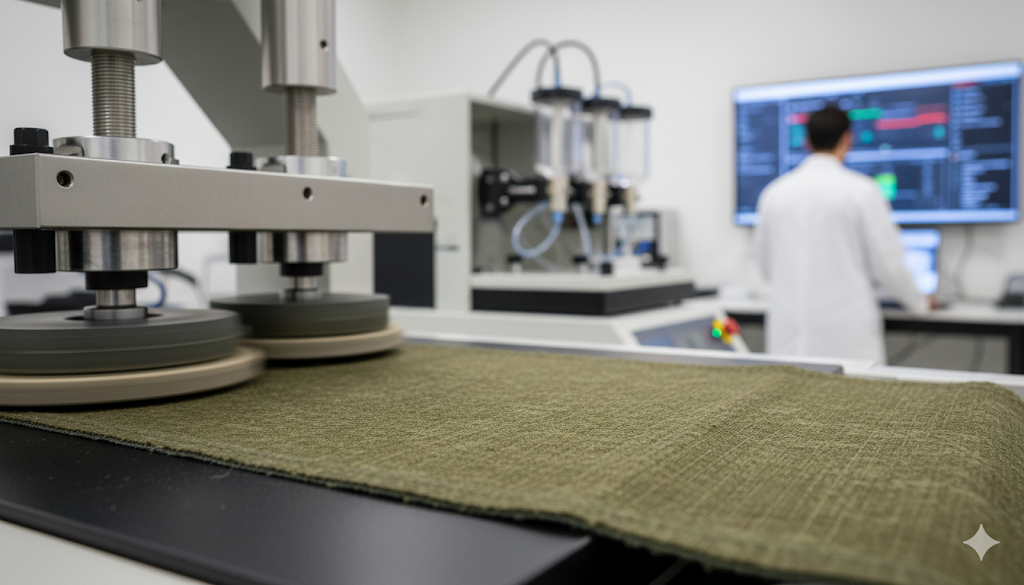

Stress and Strain: Comprehensive Durability Testing and Mechanical Integrity

The defining characteristic of technical fabrics is their exceptional durability—their capacity to withstand extreme mechanical forces without breaking down. For military textiles, protective workwear, and long-life sportswear, durability testing is a critical validation step that predicts the lifespan of the material under real-world abuse scenarios, including abrasion, tearing, and flexing.

Key Tests for Durability and Mechanical Strength:

- Abrasion Resistance: This is essential for fabrics that will be subject to rubbing, such as hiking pants, backpack material, or seating upholstery. Tests like the Martindale or Wyzenbeek methods quantify the number of cycles a fabric can endure before showing signs of wear or failure.

- Tear Strength: Measures the force required to propagate an existing tear in a fabric. This is a crucial material properties check for items that might snag or rip, such as cargo nets, military textiles, or technical tarps. Tests like the Elmendorf tear test provide quick, reproducible results.

- Bursting Strength: Critical for knit technical fabrics (like active sportswear and medical compression garments), this test measures the hydrostatic pressure required to burst the fabric, simulating stress points like knees or elbows.

- Flexing Endurance: For coated fabrics, synthetic leathers, and specialized laminates, this test ensures the material can be bent and folded repeatedly without cracking or peeling, thereby maintaining its protective material properties.

Reliable durability data derived from performance textile testing not only confirms the material’s fitness for purpose but also allows brands to predict warranties and set reasonable life-expectancy expectations for their products, further enhancing quality control.

High-Stakes Applications: Performance Textile Testing for Military and Protective Gear

A subset of technical fabrics requires testing that goes far beyond comfort and basic durability. Military textiles, medical devices, and industrial protective gear (PPE) must undergo highly specialized, often mandatory, performance textile testing to meet non-negotiable safety standards. Failure in these categories can lead directly to injury or loss of life.

For military textiles, compliance often involves adherence to strict Berry Amendment requirements and specific environmental resistance tests:

- IR/Visual Camouflage: Testing the material’s spectral reflectance to ensure it effectively conceals personnel from both the naked eye and night vision/infrared sensors.

- Ballistic Resistance: While not strictly textile testing, the fabric’s structure and layers must be verified for puncture and fragmentation resistance.

- Extreme Environmental Endurance: Testing performance after exposure to intense UV radiation, saltwater, fuel, and lubricants to ensure durability is maintained under operational conditions.

For medical textiles (e.g., surgical gowns, implants), testing focuses on biocompatibility, sterilization efficacy, and barrier protection against liquids and bacteria. Similarly, sportswear designed for extreme sports may require specialized impact absorption or thermal stress testing. In all these cases, the lab acts as the ultimate authority, providing verifiable data that confirms the material’s ability to protect the user against specific, life-threatening threats.

Elevating Performance and Safety Through Specialized Testing

The lifecycle of technical fabrics is defined by a commitment to rigorous and specialized performance textile testing. From the initial confirmation of material properties and moisture wicking capabilities to the final validation of durability for high-stakes military textiles and sportswear, expert testing is the engine of innovation and the gatekeeper of safety. Manufacturers must view laboratory analysis not as an expense, but as an indispensable investment in quality control and regulatory compliance. Only through validated, documented testing can a product claim true superiority and meet the exacting safety standards demanded by today’s sophisticated global markets. The success of advanced textiles is woven directly into the results generated by accredited, independent laboratories.

Submit a testing request today to schedule specialized performance textile testing and certification, ensuring your technical fabrics meet the highest standards of durability and safety for any global application.

FAQ

Moisture wicking refers to the fabric’s ability to move liquid sweat away from the body to the outer surface for evaporation, enhancing comfort. Waterproofing is the material’s ability to prevent external liquid water (rain) from passing through, often involving coatings or membranes. Both are critical material properties in technical fabrics, but they serve opposite functions.

Abrasion resistance is vital for military textiles because soldiers’ gear is constantly subjected to friction from equipment (backpacks, vests, webbing) and rough environmental surfaces. High durability against abrasion ensures the gear maintains its protective function and extends its service life in the field, which is a key safety standard.

The durability of sportswear (especially knits) is often tested using the bursting strength method, which measures the force required to rupture the fabric. This simulates the high stress placed on seams and material when stretched tightly over joints like elbows and knees during dynamic movement.

Technical fabrics used in Personal Protective Equipment (PPE) require specialized performance textile testing based on the threat. This includes chemical resistance, flame resistance (flammability testing), liquid barrier protection, and specific puncture or cut resistance to ensure the material meets required health and safety standards.

This article was created with the assistance of Generative AI and has undergone editorial review before publishing.